BAMP! – Building with papers (until 2021)

Natural materials such as wood or paper have been used in the building industry for several years and still play an important role in modern building and interior construction. In the BAMP! – project (building with paper) this topic was picked up to create a building completely made out of paper. The advantage of using paper as building material is the inexpensive production costs, it consists mainly of renewable resources and offers good strength properties in relation to its own weight. In addition the cellulose the paper is made of can be functionalized to create additional properties. This is necessary since paper also has some properties, which are unsuitable as building material like wettability and combustibility. Furthermore since paper is mainly made of cellulose the degradation of cellulose fibers by bacteria and mold needs to be addressed too.

These functionalizations need to be covalently attached or deeply implemented into the cellulose matrix so that the papers show over a long time period and all possible environmental influences the desired properties. In addition the influences of the modified fibres on the properties of the papers formed therefrom need to be investigated.

Antimicrobial papers

M.Sc. Oliver Elle (2017 – 2024 )

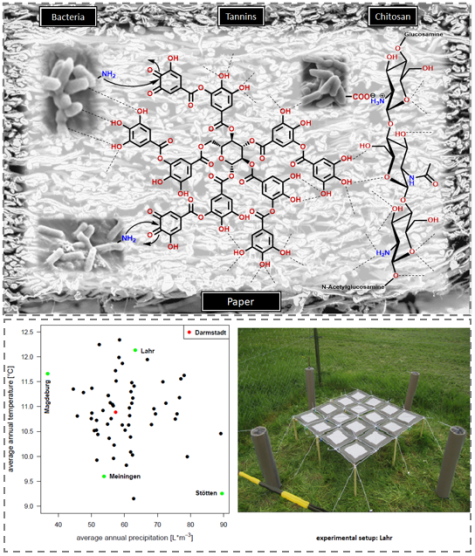

Degradation of cellulosic materials depends on abiotic as well as biotic environmental influences. As part of Loewe BAMP!, the intention is to develop paper and board houses that will meet the construction requirements in Darmstadt for a period of more than one year. For this purpose the building material and much more so the potential residents must be protected from microbial contamination. According to the WHO antimicrobial resistance has become one of the biggest threads to global health. Thus we renounce the use of antibiotics to avoid uncontrolled releases into biogeochemical cycles. Regarding antioxidant and antimicrobial properties, Chitosans and Tannins, have shown great potential as biocompatible additives.

First, we want to investigate the minimal structural functionality of our materials under real environmental conditions and identify the main degradation factors. Based on this, the targeted addition of chitosan and tannin makes it possible to adapt the service life of the papers to the respective usage scenarios.

Moisture protection of paper by superhydrophobic coating

M.Sc. Cynthia Cordt (2017 – 2021)

Super hydrophobic coatings are one effective way for the protection of paper material against water. Within the BAMP! project, a biomimetic superhydrophobic paper coating made out of purely biogenic compounds is to be developed. Such a system will be investigated using a two-component system that combines a matrix polymer with a crystallisable wax. A highly promising feature of this system is the possibility for a thermal regeneration of the superhydrophobic properties which also allows regeneration at inaccessible areas.

Biobased flame retardants on paper

M.Sc. Felix Schäfer (2016 – 2020)

Since halogen containing flame retardants cause to create toxic gases in case of fire or harm the environment through low biodegradability, the research of new flame retardant systems moved into focus. Some of those flame retardant systems contain functional nitrogen- or phosphor- groups. In addition the combination of both has a synergetic effect and is known as intumescence.

On ignition a char foam is created that at first acts as a heat shield. It also interferes with the penetration of oxygen into the decomposing substrate and reduces the emission of volatile flammable substances. The operating principle on other substrates is well known but on paper the mechanism is hardly examined. Therefore a basic knowledge and analytical methods need to be established to verify the efficiency of the intumescent system on paper substrates.

Energy-Efficient Construction by Composite Materials with Paper – KOMPAP

M.Sc. Jenny Cejmer (until 2018 ), Sabrina Mehlhase ( 2018-2019)

The aim of the KOMPAP project is the development of a new energy efficient construction material based on paper and a mineral matrix like (foam) cement, concrete or geopolymers. In sandwich processing, it can contribute to energy optimization through its heat-insulating properties or it can be used as a crack-bridging exterior facade.

In the beginning, we want to gain insights about structure-property relations of such paper – hybrid – materials. For this purpose, a fibre passivation by silanes is carried out, which is to protect the paper from the strongly alkaline medium (pH ≥ 12,6) of the mineral matrix. A reactive functionalization of the silanes should be used to develop an adhesion optimization between the two materials. Finally, the knowledge gained can be transferred to other paper composites such as, for example, a paper-plastic composite.