Improving the recyclability of wet-strength papers

The paper production industry has made significant progress in the circular economy, with recovered paper being the most important raw material. In Germany, the usage rate of recovered paper has steadily increased to 83 % in 2023. However, some standard paper and board grades, in particular wet-strength papers, remain largely non-recyclable. These standard wet strength papers also suffer from problems such as insufficient biodegradability, dependence on fossil raw materials, and the production of toxic by-products.

M.Sc. Nicole Kirchner (since 2024)

This project aims to develop bio-based and recyclable alternatives to conventional wet strength agents. The goal is to create new, adaptable agents that maintain the strength of the paper during use while being easily separable during recycling. Understanding the deposition and mechanisms of common wet strength agents such as PAE is therefore a crucial first step. This knowledge must then be applied to gain a fundamental understanding of the effects of paper properties such as wet strength on paper recyclability. This will be achieved through a combination of imaging techniques and fiber property analysis, cross-referenced with recycling experiments. In a subsequent step novel wet strength agents will be developed by utilizing the results of the previous research fields.

M.Sc. Tobias Gaydoul (since 2025)

Recently, CeraSleeve® developed a process to incorporate silica as wet-strengthening agent into paper. These silica-based paper hybrid materials were observed to curiously display both a strong ability to generate wet-strength whilst at the same time showing best-in-class repulpability. To explain this, it is key to figure out how the wet-strength development in these silica-paper hybrids can be mechanistically understood. Our work not only aims to thoroughly investigate the potential of silica as a novel wet-strength agent regarding sustainable paper recycling by testing the impact of different production parameters on properties such as wet-strength and recyclability. Further we hope to gain a more fundamental understanding through studies of distribution as well as mechanical and surface properties.

More efficient drying of paper by chemical modification and additivation

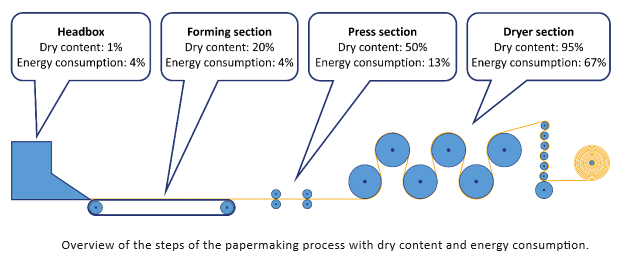

The paper industry is the fifth most energy-intensive industrial sector in Germany. It is responsible for 1.9 % of total energy consumption and 1.75 % of total greenhouse gas emissions in Germany. In 2023 research institutes, industry and politics came together to form the "Forschungscluster Modellfabrik Papier“ (FOMOP). Its aim is to optimise paper production processes to reduce their energy consumption by 80 % until 2045. This is to be achieved through the development of new technologies for a sustainable, climate-neutral and forward-looking paper industry.

One focus of the project is to optimize the paper drying process, which is one of the most energy-intensive steps in papermaking.

This group's approach to reducing drying energy is to adjust the water retention value of the cellulose fibres. This is achieved through fibre modification and additivation.

M.Sc. Nils Sauer (since 2024)

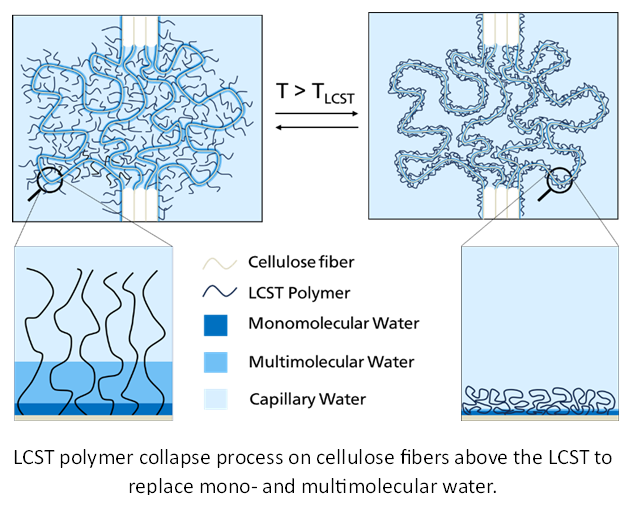

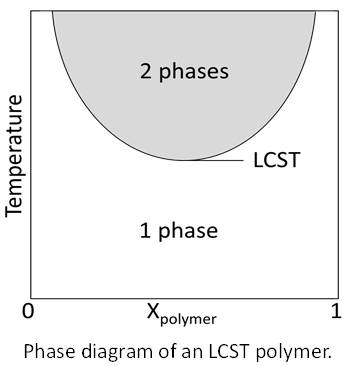

Nils Sauers strategy is to modify cellulose with polymers which have a lower critical solution temperature (LCST). These polymers collapse above their LCST temperature. During the paper drying process the polymers collapse onto the cellulose fibres and displace the highly bound mono- and multimolecular water. The remaining capillary water requires less energy to remove.

M.Sc. Nele Link (since 2024)

Chaotropic agents are known for their ability to reduce the hydrophobic effect and therefore increase the solubility of hydrophobic molecules. These effects are based on the ability of chaotropic agents to disrupt ordered hydrogen bonds and increase the entropy of water. Nele Link is investigating the effect of chaotropic agents on the interaction between cellulose fibres and water.

M.Sc. Jake Appelhans (since 2025)

Carbohydrate Binding Domain (CBM) proteins can bind to cellulose. Through protein modification, for example, using the grafting-to method, CBMs can be modified with polymers, which can be attached to lysine residues on the protein surface. These polymers can include lower critical solution temperature (LCST) polymers, which collapse above their LCST and expel the solvent. This property is intended to reduce drying energy consumption in the paper manufacturing process.

Potential LCST polymers include PolyNIPAM or HPC (Hydroxypropylcellulose), as well as biochemical LCST polymers such as elastin-like polypeptides (ELP). In combination with CBMs, LCST polymers are expected to enable efficient attachment to paper fibers, thereby reducing energy consumption during the drying process in paper production.

Investigation of capillary rise

M.Sc. Patrick Galenschowski (since 2023)

The aim of the project is to gain a better understanding of capillary rise in paper-based materials in order to determine different material properties, such as pore radius, porosity, contact angle and fibre roughness. With our self-developed rotation device, the equilibrium state, which occurs under rotational conditions during the imbibition of water in paper, is investigated for different rotational speeds. This approach was developed in order to be able to neglect various effects that play a role in the dynamics of imbibition. Nevertheless, previous work has shown that it is not sufficient to consider only capillary and centrifugal force for the theoretical modelling of the capillary rise height. We extended the model to include the effect of angular velocity dependent evaporation and found a good agreement between the measured data and the model. In order to verify the evaporation rate resulting from the fitting of the model to the data of the rotation device, a vertical imbibition experiment is also carried out, in which the evaporation rate is determined gravimetrically under controlled humidity.

In addition, the surface or fibre roughness has also been integrated into the model. In order to demonstrate their influence experimentally, roughened glass capillaries and porous glass were rotated in addition to paper substrates. Thirdly, we investigated the question of whether, despite the equilibrium state of the imbibition, (local) currents occur under rotational conditions that can also have an influence on the exposure distance. This question was experimentally realized with fluorescent particles added to the liquid and coaxial zoom optics.

Gaining better understanding of the mechanisms using wet strength agents for paper production

M.Sc. Jan-Lukas Schäfer (2018 – 2023)

Wet strength paper has a broad range of application from tissue paper at home to lateral flow tests in paper-based analytics. Since paper built entirely out of cellulose fibres has no intrinsic strength in the wet state, the papermaking industry uses wet strength agents. Commonly used are polymers which attach to the fibers and shield them from water. After the papermaking process the papers are thermally annealed to attach the polymers to the fibers, which requires a lot of energy and has a high environmental impact.

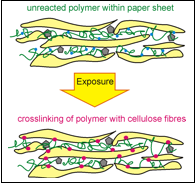

That’s why the research and development of new wet strength agents is of great importance. Photoreactive copolymers which are activated by UV-light can be used to covalently bond the fibers in the paper to each other and induce wet strength. Furthermore using fluorescently labeled polymer systems should allow for a better understanding of the mechanisms behind wet strength agents and how to improve their use in the papermaking process.

Towards reducing sensitivity loss in microfluidic paper-based analytical devices

M.Sc. Alexander Ritter von Stockert (2018 – 2022)

Paper-based analytics provide a large array of potential uses, ranging from medicine, over environmental studies, to quality control in the food industry. While those devices excel in fields such as availability, cost and stability, they often lack the desired sensitivity that is needed to detect trace amounts. This can be due to unspecific adsorption to cellulose fibers, or to diffraction of light of colorimetric displays.

To combat the unspecific adsorption of proteins to the fibers, the interactions need to be determined first and later suppressed, by the use of specific polymer coatings. The second block is accompanied by the principle of diffraction between two media with different diffraction indices. By changing that of the paper, to be closer to the one of air, a lower detection limit could be reached. The use of different fiber sources and paper porosities should yield a further understanding of their impact on fluid transport and unspecific adsorption.

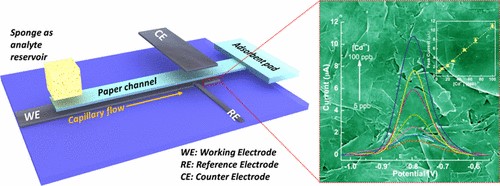

Immobilization of ionic liquids in microfluidic papers as basis for electrochemical sensors

M.Sc. Tizian Venter (2018 – 2021)

Functional composites of IL (ionic liquids) and microfluidic paper represent a new platform for electrochemical applications, especially sensors. These composites have the potential to circumvent the disadvantages of systems based on aqueous electrolytes (low potential window, evaporation losses and resulting measurement errors) and may additionally exploit the solubility properties of the IL for the selective enrichment of analytes. A possible application example may be the qualitative and quantitative analysis of heavy metal ions. Heavy metal contaminants can not biodegrade, posing a long-term problem for the ecosystem. Current standard procedures for analyzing such pressures require laborious laboratory studies. Simple methods for on-site diagnosis, such as paper-based electrochemical sensors, which can be carried out with little outlay on equipment, therefore have tremendous innovation potential. Due to the possibility of local control of paper properties such as e.g. the surface functionalization or porosity can be realized in microfluidic papers a defined liquid transport for the sensors.

Techniques to produce and analyse microfluidic channels

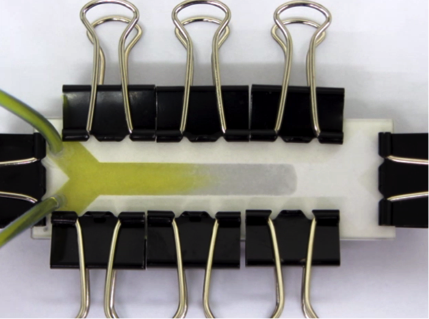

M.Sc. Niels Postulka (2017 – 2021)

Microfluidic devices gained a growing interest over the last decades, especially their potential in point of care diagnostics, food safety, environment monitoring and veterinary medicine. The aim of the devices is to analyse an analyte for selected substances. Therefore, the compounds could be divided into a substrate to transport the analyte to one or several detectors to qualify and in some cases quantify the substance. One possibility is using paper-based substrates.

This material provides interesting properties including porosity, through which liquid transport is possible, without using external pump systems. Since for microfluidic just small amounts of analyte are needed, it is necessary to modify the paper in structured hydrophobic and hydrophilic areas. To archive those properties there are several methods e.g. printing hydrophobic substances like wax onto paper, photolithography or 3D deformation of paper.

Tailorable fluid flow speed in paper using polymers

M.Sc. Marcel Krauße (2016 – 2020)

Within the Merck Lab we are focused on the development of novel paper- based, low- instrumented analytical devices. This implies an extensive understanding of the interactions between paper and analytes, the fluid flow properties and ways how paper can be functionalized with antigens, enzymes etc. Newly developed paper based (hybrid) materials have to be tailored, functionalized and investigated. Well- established platform which are widely used in diagnostics and life science, as e.g. the home-use pregnancy test, are used for benchmarking.

The combination of cellulose (paper) and polymers enables the tuneability of fluid flow properties in tailor-made materials. The fluid flow is defined by the inherent porosity and surface chemistry of cellulose fibers and can be modified by using polymers. Those defined materials can be used to tune the fluid imbibition and could be applied as e.g. µPADs (Microfluidic Paper-Based Analytical Devices).

Dye, peptide and protein retention in paper-based microfluidic devices

Dr. rer. nat. Sonja Wendenburg (until 2018)

Paper-based microfluidic devices provide interesting applications, including clinical “point-of-care” diagnostics, food quality control and environmental monitoring. Paper as a matrix for microfluidic devices offers many advantages compared to other materials, particularly due to its capability to transport liquid by capillary forces.[1]Current research on paper-based microfluidic devices focuses only on commercial available filter paper. Thus, a huge engineering potential for paper-intrinsic parameters is lost.

In our group in general, and in particular in this project, the influence of paper sheet parameters on lateral flow in paper-based micro-engineering devices[2] as well as the retention of dyes, peptides and proteins is under investigation with the aim to improve “lab-on-a-chip” devices. Firstly, we are investigating the influence of paper substrate (different grammages, fibre types, …) and solution parameters (type of retaining molecules, pH-value…) on retention. In a second step, we plan to control the retention. This will be realized by modification of paper substrates with functional, photo-reactive polymers. “0-retention” is interesting for “lab-on-chip” devices to reduce sample volume and increase sensitivity, while site-specifically huge retention might be interesting for analyte filtration.

In our group a novel lithographic process for site-specific modification of cellulose fibers in paper-sheets using photo-reactive, functional polymers was developed[3]. In our approach, paper is site-specifically and covalently microstructured in Y-shaped channels by UV-irradiation using copolymers based on methyl methacrylate or styrene and 4-methacryloyloxy benzophenone (MABP), as a photo-crosslinker. The polymer can be transferred onto the fibers by various means, including dip-coating or doctor-blading. For covalent attachment, polymers are bound to the fibers by illumination of the sheets with UV-light, and non-bound polymers (i.e. polymers within shaded areas) are subsequently removed by simple solvent extraction. So prepared, chemically structured papers consist of hydrophilic channels that are defined between hydrophobic coats. To quantify the retention by the retention factor Rf, a (dye) solution (here: 0,8 mg/ml tatrazine in H2O, pH1) is applied to a micro-structured paper substrate (here: Linters, 45 g/m²) and the migration distance of the dye is divided by the migration distance of the water front.

Related publications

[1] D.D. Liana, B. Raguse, J.J. Gooding, E. Chow, Sensors, 2012, 12, 11505.

[2] A. Böhm, F. Carstens, C. Trieb, S. Schabel, M. Biesalski, Microfluid Nanofluid, 2014, 16, 5, 789-799.

[3] A. Böhm, M.Gattermayer. F. Carstens, S. Schabel, M. Biesalski, Advances in Pulp and Paper Research, Trans XVth Fund.Res.Symp. Cambridge 2013, (S.J.I’Anson, ed.) 599-618.

Development of novel wet-strength additives

M.Eng. Michael Jocher (until 2014)

Wet strength resins are widely used in manufacturing paper and paper products, which need to preserve mechanical strength even if they are completely saturated with water. There are many paper grades which need to be wet strengthened for example: wall paper, security papers, tissue grades, laminating papers, label papers, filter papers, tea bags, abrasive papers, some liner and more. The most important wet strength additives are polyamidoamine epichlorohydrin resins, melamin- and urea formaldehyde resins, which imply permanent wet strength and glyoxal resins, which serve as temporary wet strength agents.

There are big disadvantages with respect to common additives used in paper making:

Epichlorohydrin resins:

➢ Low curing off machine

➢ Problematic low molecular chlorine compounds (by-products)

➢ Hazardous to health and detrimental to AOX load

Formaldehyde resins:

➢ Application just in acidic paper making conditions

➢ Limited use in wet end application

➢ Formaldehyde emission (carcinogeniticity)

We are currently working on alternative approaches in using polymers, which shall not contain problematic substances and shall chemically attach to cellulose fibers, both through heat and/or light exposure.

Advantages are:

➢ Achieving a well defined wet strength with less further post-process curing events

➢ No bleeding-off organic substances from paper

➢ Curing during converting step on demand, thus easier broke handling

➢ Adjusting different rates of wet strength even in cross-process direction