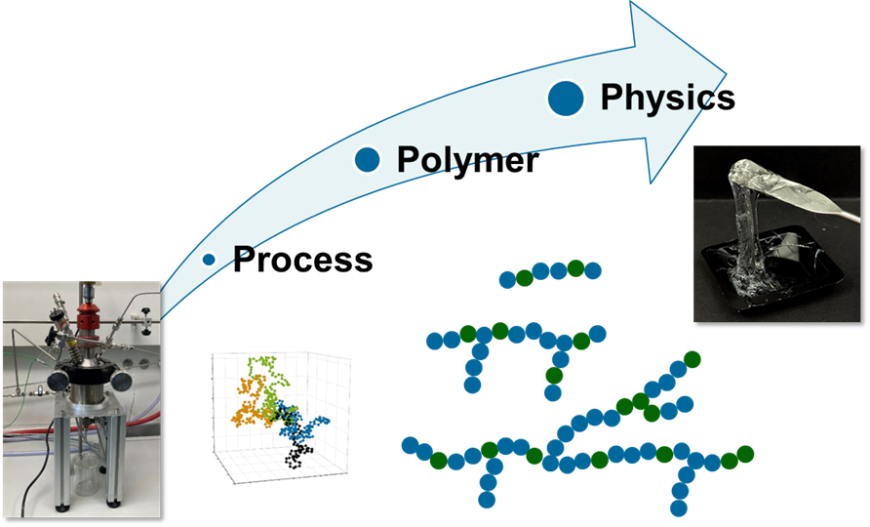

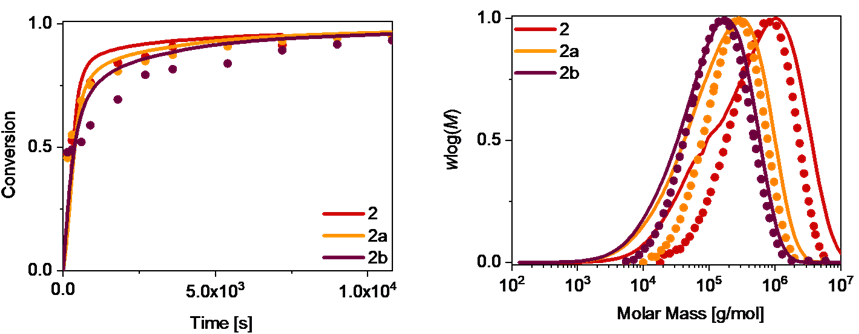

In the first step, the process conditions and the kinetics of polymerization are taken into account and mass, heat and, if necessary, momentum balances are solved numerically in a deterministic simulation using Predici (CIT – Computing in Technology). From this, among other things, conversion profiles, molecular weight distributions and average polymer properties such as copolymerization compositions or branching lines are obtained.

The deterministic simulation also provides event probabilities, which are used in the next step in a hybrid stochastic Monte Carlo approach to generate individual topologies of branched macromolecules. These topologies can then be used to predict the rheological properties (flow characteristics) of the bulk materials via the branch-on-branch (BoB) algorithm.

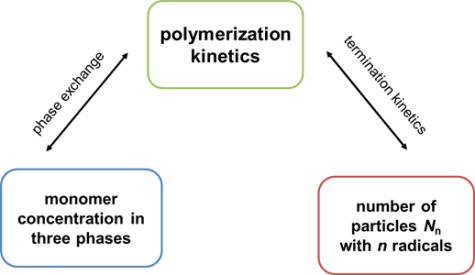

When modeling emulsion polymerizations, the multiphase nature of the system is added to the consideration of polymerization kinetics, process conditions and reactor configuration. Initiation and subsequent oligomer growth take place in the aqueous phase. Subsequently, the oligomers enter the particles in which further growth and all secondary reactions such as transfer reactions and termination take place. For the termination it has to be taken into account that polymer radicals can only terminate with radicals in the same particle – this is due to the so-called compartmentalization. At the same time, the concentrations of all species – first and foremost the monomers – in the different phases must be known at each time step.

[1]https://onlinelibrary.wiley.com/doi/full/10.1002/marc.202100620