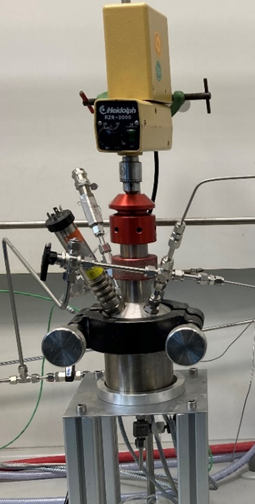

A high-pressure reactor with a volume of 0.5 L and a maximum pressure of 300 bar is available.

The connection to two high-pressure dosing pumps including storage vessels enables variable dosing of liquids as feed. In addition, targeted gas dosing is possible (Coriolis MFC). Thus, in addition to batch operation, semi-batch operation and continuous operation are also possible.

The polymer products are extensively characterized, especially with respect to molecular weight by (high-temperature triple detection) gel permeation chromatography (GPC), particle size by dynamic light scattering (DLS), glass transition temperature by differential scanning calorimetry (DSC) and copolymer composition and microstructure by NMR. Analytical equipment in the RG Busch and the analytical department of the chemistry faculty are available for this purpose.