Nanomechanical Characterization of functional fibres and fibre joints in paper

In the design of papers with functional properties, the modification of the pulp fibre itself or the fibre-fibre connection by means of polymers plays an important role. This raises fundamental questions: what is the spatial distribution of the polymers on the fibres and at the fibre-fibre intersections? How can the fibre coating be locally probed, e.g. on the fibre or in the fibre connection? How do the mechanical properties of the fibre change when wetted? How does the wet tensile strength of the paper change through the coating? It is therefore the aim of this project to investigate functionalized fibres, fibre-fibre connections and cut-outs of the fleece using high-resolution force microscopy methods and micro tensile tests in order to better understand the relationship between the mechanical properties of functional papers on the macroscopic and microscopic level.

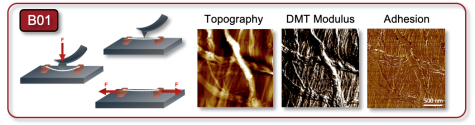

The Atomic Force Microscope (AFM) shall be the central tool in the characterization of individual fibres or their compounds in this project due to the high spatial and force resolution. In addition, chemical mapping with a confocal Raman microscope is used to chemically detect the coating. The special focus of the research project will be on polymer-associated or polymer-modified papers. The aim is to investigate how the functional polymers in the fleece and on the fibres are distributed, how well the chemical functionality of the polymers in the fleece remains dry and wet, and how the nano-mechanics of the polymers affect the mechanics of the fibres and the strength of the fibres. Characterization with the AFM makes it possible to visualize the distribution of the polymer and to detect changes in the local mechanical properties of the fibre. The AFM is complementary to confocal light microscopy and electron microscopy and offers the possibility to visualize the fibre morphology and nano-coatings. At the same time, local mechanical properties (elasticity, viscosity), tribological (friction, adhesion) or electrochemical (surface charge) properties can be measured with high spatial resolution and high sensitivity. With the help of AFM analysis and in a micro tensile test, the behaviour of individual fibres and of fibre-fibre compounds in the dry and moist state under mechanical stress is to be investigated. This knowledge is reflected back into the papermaking projects and at the same time forms the basis for the parameterization of the material parameters in simulation calculations.