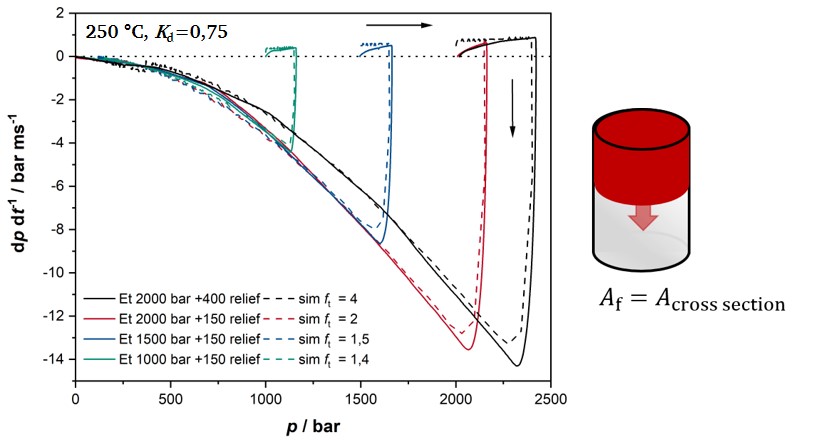

The highly dynamic decomposition reaction of high-pressure polymerization mixtures with or without subsequent pressure relief is characterized by means of modified thermocouples and piezoelectric pressure transducers. Research is focused on the phenomenological description of those deflagrations with co-monomers as well as the influence of the polymer component. Simulative analysis is used to support the characterization of decomposition and relief phenomena, whereby the relief is described by nozzle models and the decomposition reaction by combustion models. The fresh gas and the burnt phase are thermodynamically described with real gas equations of state. The composition of pyrolysis gas depends on the reaction conditions. The methodology of gas chromatography (GC) allows the qualitative and quantitative determination of those. The method development for safety valve design is another long term goal of this research topic.